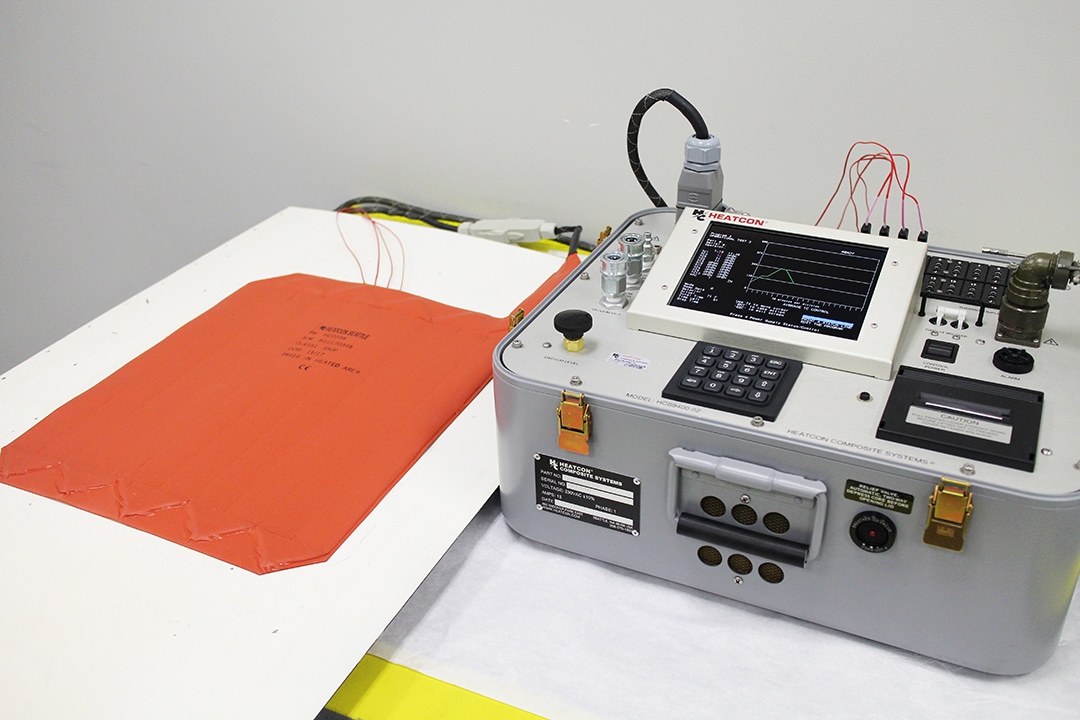

HCS9400-02 – Smart Susceptor™

Thermal uniformity is critical in composite curing to achieve designed material properties.

The HCS9400-02 Smart Susceptor™ technology addresses this challenging issue and represents a revolutionary concept in composite curing through the use of inductive heating.

The Smart Susceptor System performs an active role in heat distribution by reducing heat to areas at the process temperature while continuing to heat cooler areas. This process improves thermal uniformity to enable the composite materials to properly cure.

- Sunlight Readable LCD Display: 5in x 4.75in

- (12.7cm x 12.06cm)

- Input: 230 VAC ±10%, 15 Amps

- Output power capacity: 2,000 Watts

- Control Parameters:

- Temperature Accuracy: /- 1° F (0.55° C)

- Vacuum Resolution: 1 inHg

- Vacuum Accuracy: /- 1 inHg

- Vacuum Monitoring Capability: 30 Hg

- Control Methods:

- Hottest Thermocouple

- Coolest Thermocouple

- Thermocouple Average

- Thermocouple No. 1

- Thermocouple No. 2

- Control/Monitor Toggle for Individual Thermocouples

- Up to Eight (8) Ramps and Dwells per Program

- Program Storage Capacity: 30 separate operator-entered programs

- Over 500 hours of Cure Information (12 Cure Records)

Stored for Data Export and Printing - Power Failure Auto Recovery:

- Default power recovery within 2 minutes of power loss results in continued program operation

- Programmable 1-15 Minute Auto-Recovery with Continued Program Operation

- Cure Data Download: USB port for data export

- Dynamic Alarm / Control Integration

- Alarm Volume: 90dB, Adjustable Volume

- Text Entry System with Alphanumeric Keypad

- Selectable Metric or English Units

- Susceptor Heat Blankets

- Input Cable

- Output Susceptor Cable

- Thermocouples

- Vacuum Hose

- Air Filter

- USB Drive with Data Capture Analysis Software

- Extra Printer Ribbon and Printer Paper

- Software security lock with password access

- Multiple Ramp / Soak Capabilities

- Special Hot Bonder/cure process training