HCS3100 – RepairClave

The HCS3100 RepairClave is a semi-portable pressure vessel designed to provide controlled temperature, vacuum, and pressure during composite and metal bond repair processes.

RepairClaves are custom built with standard vessel lengths starting at 3ft up to 30ft (progressing in 3ft increments).

United States Patent and Canadian Patent Technology

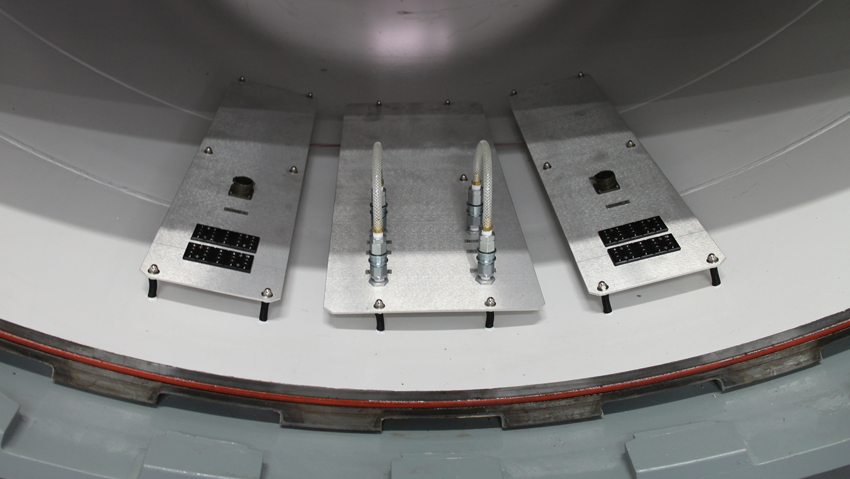

RepairClaves are custom built with optimized interior space and internal connectors for easy use. When in operation, positive internal pressure is applied to the composite repair to achieve the higher pressure when required.

The RepairClave is ideal for repair applications that include helicopter blades, thrust reversers, cowling, flaps, or ailerons.

Feature Include:

- Localized heat

- Controlled temperature

- Vacuum and pressure functionality

- Heatcon hot bonder technology

- Removable part carrier

- Lighted interior

- Adjustable operating pressure

- Flanged access ports

Standard Specifications*:

| Type | Specification 1 | Specification 2 |

| Vessel Dimensions | Length: 03ft – 30ft (3ft increments) |

Inside diameter: 3ft or 4ft |

| Power System | Voltage: 120-240V, 1-phase to 480V, 3-phase | Amperage: customer configuration |

| Control System | 2-zone | — |

| Vacuum System | Electric vacuum pump per zone | — |

Construction:

- Vessel – from certified rolled plate steel material (SA516-70)

- Hinged Closure – various mechanical locking devices available

- Closed End – welded domed tank head

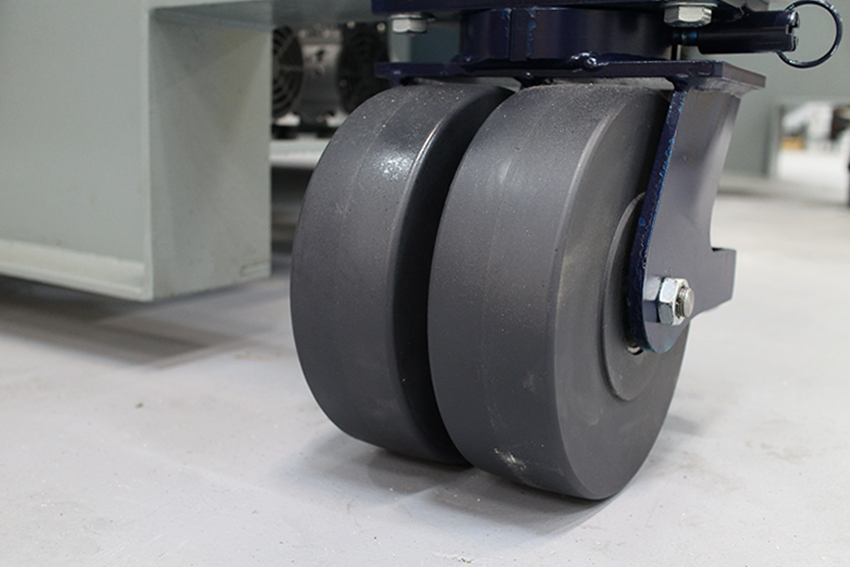

- Locking Casters/Floor Jacks – for mobility and stabilization

- Multiple Auxiliary Ports – for needed expansion

Operating Pressure:

- ASME Certified Vessel – 150 psi max pressure at 400° F

- Nominal operating pressure – 100 psi

- Certified pressure relief valve

*Specification may be customized upon request

The HCS3100 Repair has the following standard options.

- Vessel Inside Diameter: 3ft, 4ft, or 6ft

- Vessel Door: Hydraulic functionality needed for 6ft option

- Vessel Length: 3ft, 10ft, 12ft, 20ft, or 30ft

- Control System: 2-zone

- Thermocouple: 10 per zone

- Electrical System: 2-zone power distribution (single phase) or 480V power distribution per zone

- Vacuum System: 1-onboard electric vacuum pump per zone

- Pressure Control: Pneumatic System

- Fire Suppression System: Stand-alone (independent of control system)

Depending on order, packaging can vary.

- Transportation will be set-up at time of order

- Custom built crate services when necessary