HC99 Series-Heat Forming Kit (PVC Trim and Dial Controller)

Heat Forming Kit: PVC Trim (Dial Controller)

The HC99-100 and HC99-200 series (dial controller) heat forming kits contains all the necessary components to heat and form cellular PVC trim. Select the best kit for your application. Heat blanket sizes vary in each kit.

Heat Forming Kit Includes:

• 2- heat blankets (fixed sizes in kit)

• 1- temperature controller

• 1- pair of gloves

• 1- infrared heat gun

• 1- case (with custom foam lining)

NOTE: DUE TO THE IMPACT OF COVID-19, WE ARE EXPERIENCING A COMPONENT AVAILABLITY SHORTAGE. OUR CURRENT ESTIMATED SHIP DATE IS END OF MAY 2021. WE APPRECIATE YOUR PATIENCE AND APOLOGIZE FOR ANY INCONVENIENCE.

Related products

The dial controller heat forming kits (HC99-100 and HC99-200) consists of a temperature controller that uses a basic low to high function. To monitor the temperature, an infrared heat gun is included with these kits.

- Dial temperature control system

- Easy setup

- Uniform heating

- Rapid heating

- Lightweight portable case

- Kits are packaged with fixed heat blankets sizes

Each HC99-100 and HC99-200 heat forming kits (dial controller system) includes 2 heat blankets, 1 temperature controller, 1 pair of heat gloves, and 1 infrared gun packaged in a foam lined case. Additional heat blankets and accessories are available and sold separately.

- (A) Kit 120V | 15Amp | 2 heat blankets – 6″ x 96″ – HC99-200-22

- (B) Kit 120V | 15Amp | 2 heat blankets – 7″ x 84″ – HC99-200-23

- (C) Kit 120V | 15Amp | 2 heat blankets – 5″ x 120″ – HC99-200-24

- (D) Kit 120V | 15Amp | 2 heat blankets – 5″ x 64″ – HC99-100-111C064C1

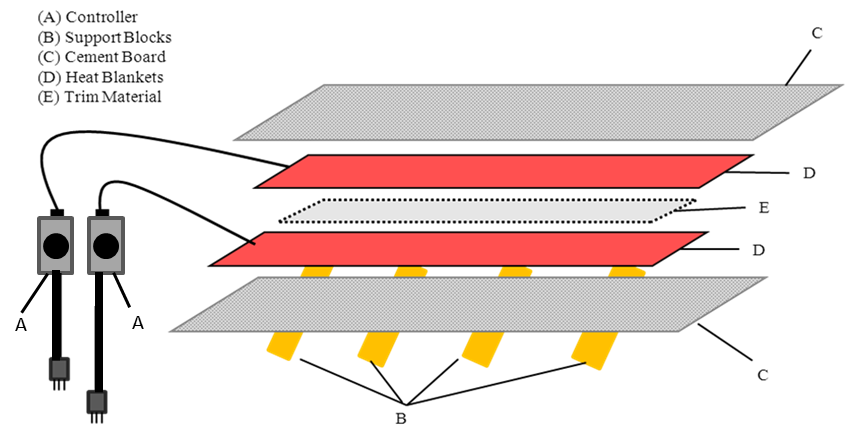

What is a typical setup?

A typical setup for heating a piece of PVC trim is shown below.

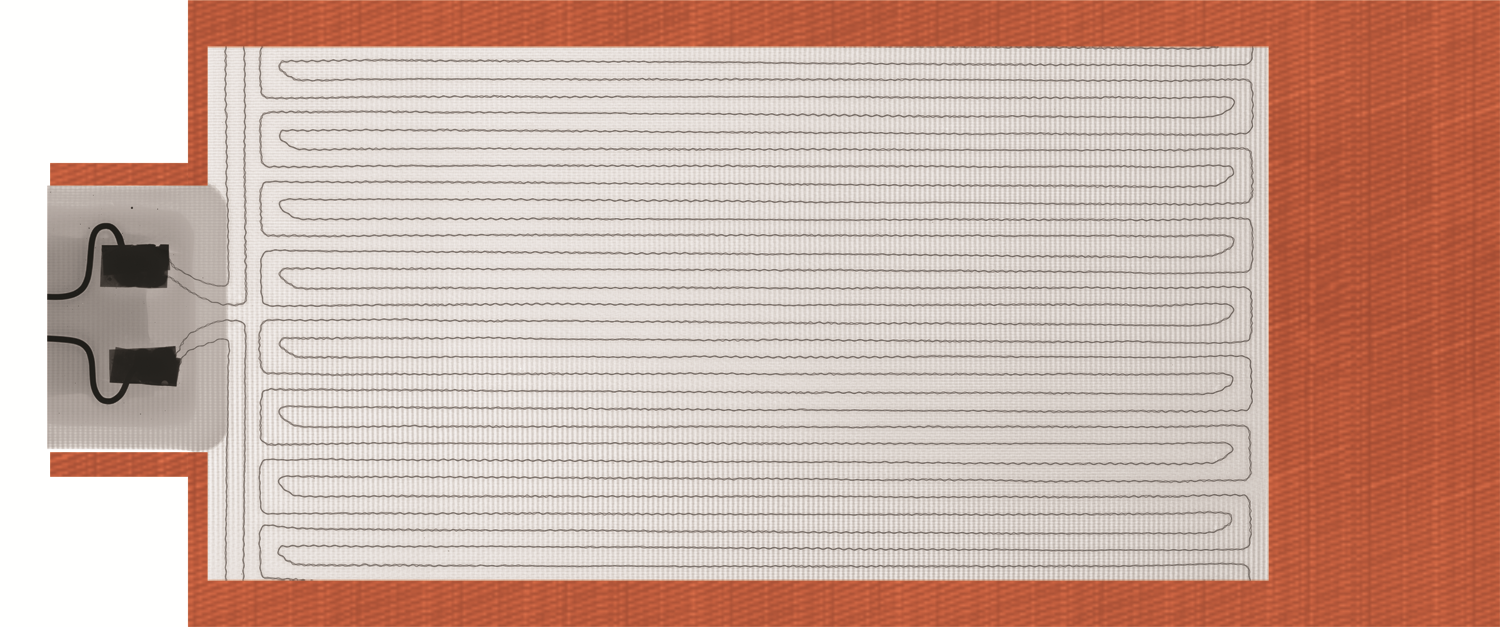

What makes the blankets heat up and how hot can they get?

Each heat blanket is manufactured in our factory in Seattle, WA. The heat blanket technology is derived from our aerospace composite repair business. Each blanket has a series of evenly spaced distributed wires inside the blanket material (see illustration below). The wires are encapsulated in a high temperature silicone rubber material and then a protective layer of woven fiberglass materials is applied for extra protection.

Cut Away view of Wires

How long will the heat blankets last?

If the heat blankets are handled and stored properly the heat blankets should last for years. We have had PVC trim kits in the field for over a decade with all of the original equipment still in use. If the blankets are not handled as outlined in our heat blanket care instructions and user’s manual, the life of the blankets maybe shortened.

Why do I need a temperature controller for the heat blankets?

The heat blankets require a temperature controller to regulate the heating process. The temperature controller is simple to operate, and internally it performs some complex tasks. The controller reads two different temperature readings from thermocouples (one from each blanket). It then utilizes the thermocouple feedback to calculate the needed output to heat up each blanket. Without the controller the heat blankets will simply overheat.

There are other ways of heating up PVC trim materials, what makes the HEATCON system different?

Other heat forming methods such as tube heating systems will work. Tube heating systems may not provide an even heat across the length of the board. This may cause the board to overheat on one end and not heat up enough in the center, making it difficult to bend. Heatcon’s system is lightweight and portable and provides an even heat across the entire board.

Why is concrete board used in the heating process and can I use other materials to insulate the heat?

The heat forming procedure recommended by HEATCON utilizes standard concrete board or concrete siding in the heating process. The purpose of the concrete siding is to keep the heat insulated between the heat blanket and material. It also helps to keep the heat blanket flat and in place against the PVC material. We recommend having at least 2” concrete board overlapping the heat blanket.

What outside forces can affect the heating process?

Outside forces such as wind and cool ambient temperatures may affect the heating process. Performing the heating forming procedure out of the wind and in warmer ambient temperatures will improve the heating process.

Why is there an odor during the heat forming process?

The PVC material will release an odor from heating the material. It is recommended to perform the process in a well-ventilated area.

Can I bend all PVC trim brands and what temperatures do I need to reach?

Most PVC trim materials offered today will require the material to be heated anywhere from 290F to 300F for 15-30 minutes to achieve a radial bend. Once the blankets are heated up the second piece of material will heat at a faster rate.

Can I use the HC99-200 PVC trim heat forming kit to form composite decking material as well?

The PVC trim blankets are not recommended for heating composite deck boards, the blankets heat at a faster rate than our standard deck blankets. PVC trim requires more heat and can be heated at a faster rate than decking materials due to the material composition. Decking material is thicker and contains less PVC than interior trim, so the deck blankets are designed to heat at a slower rate to allow the heat to radiate through the material.

How do I heat up a board that is shorter than the heat blankets?

Heating narrow or shorter pieces of material can be accomplished by using filler boards. It is recommended to use a piece of the same material, and color, as the board you are forming to maintain consistency in the heating process. It is also recommended to rotate cool filler boards in and out of the process if heat forming multiple boards. Do not use wood boards or treated lumber as they will not transfer the heat consistently.

Also remember that blankets should not touch for an extended period of time during the heating process due to extreme heat they generate.

How do I heat up a board that is longer than the heat blankets that I have?

If you are heating up a board that is longer than your heat blankets it is possible to heat up a section of the board and then form that heated section. Then heat up and form the remaining portions of the board. The results will vary depending on the radius and experience of the user.

You can also use multiple heat forming kits to lengthen your heating surface. The heat blankets can be butted up end to end to make a longer heating surface.

Can I heat up a piece of material that is the same width as the heat blankets?

It is recommended to have at least a ½” of extra blanket on each side of the material to provide a full surface area over the board.

If heating up a board that is the same width as the blankets you will not be able to achieve a maximum radius or bend. Even though there is heat across most of the surface of the material, the outside of the material is exposed to the outside air temperatures. This does not allow the outside edges of the board to maintain the same heat level as the rest of the material under the heat blanket.

Will the size or texture of the PVC material change during the heating process?

All PVC material brands will react differently. It is common for most materials to expand very slightly. Some textured PVC trim boards will lose their texture feel and look after being heat formed. It may be a good idea that to test a piece of material before proceeding with a full project.

What is the difference between the Dial Style Control and the Electronically Controlled Heat Forming Kits?

The dial style control kits and electronically controlled kits each come with a different style controller. The dial style controller has a basic Low to High function (like a kitchen oven countertop controllers) and temperatures are monitored using the supplied infrared heat gun. The electronically controlled kit has a more sophisticated controller. The temperature reads out on the controller and you can set the goal temperature with the built in digital timer. The heat blankets have a temperature probe built into the blanket, this probe is then plugged into the controller. The controller will monitor and control the heating process and alarm the user when the goal temperature is reached.